FAQ

Compressor unit - key components and applications

Accreditation

Contact information and request

We specialize in conducting comprehensive testing of compressors and condensing units, which are key components of refrigeration systems.

We have modern test stands and a team of experienced specialists, which allows us to provide services at the highest level in accordance with the standard:

PN-EN 13771 - Compressors and condensing units for refrigeration systems.

What does the compressor testing offer look like?

Compressor Testing

Compressors are a key component of refrigeration systems, responsible for the circulation of the refrigerant. We offer a wide range of studies, including:

- Refrigeration Capacity: Evaluation of the compressor’s ability to effectively cool under various operating conditions.

- Drive Power: Measurement of the energy consumption of the compressor during operation.

- Energy Studies: Analysis of the performance and energy efficiency of compressors with capacities ranging from 5 to 30 m³/h.

- Safety Studies: Compliance tests with safety standards, including risk assessment and device reliability evaluation.

Condensing Unit Testing

Condensing units play a crucial role in the process of heat removal from refrigeration systems. Our studies include:

- Condensation Efficiency: Evaluation of the unit’s ability to remove heat and condense the refrigerant.

- Drive Power: Measurement of the energy consumption of the unit during operation.

- Energy Studies: Analysis of the performance and energy efficiency of condensing units with capacities ranging from 5 to 30 m³/h.

- Safety Studies: Compliance tests with safety standards, including risk assessment and device reliability evaluation.

cIs our laboratory accredited?

Yes, our laboratory has the appropriate accreditations, which guarantees the high quality and reliability of the tests performed.

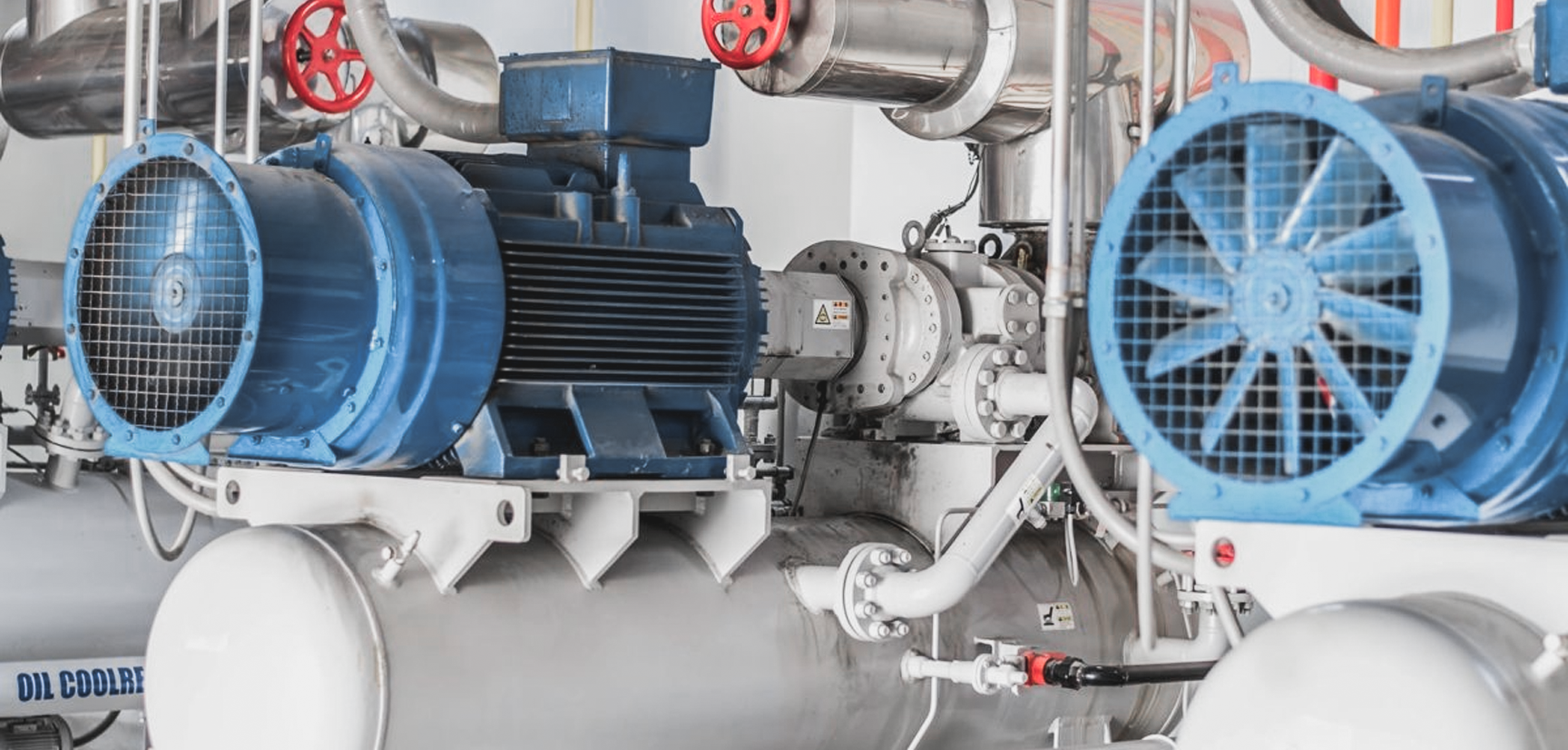

Compressor unit - key components and applications

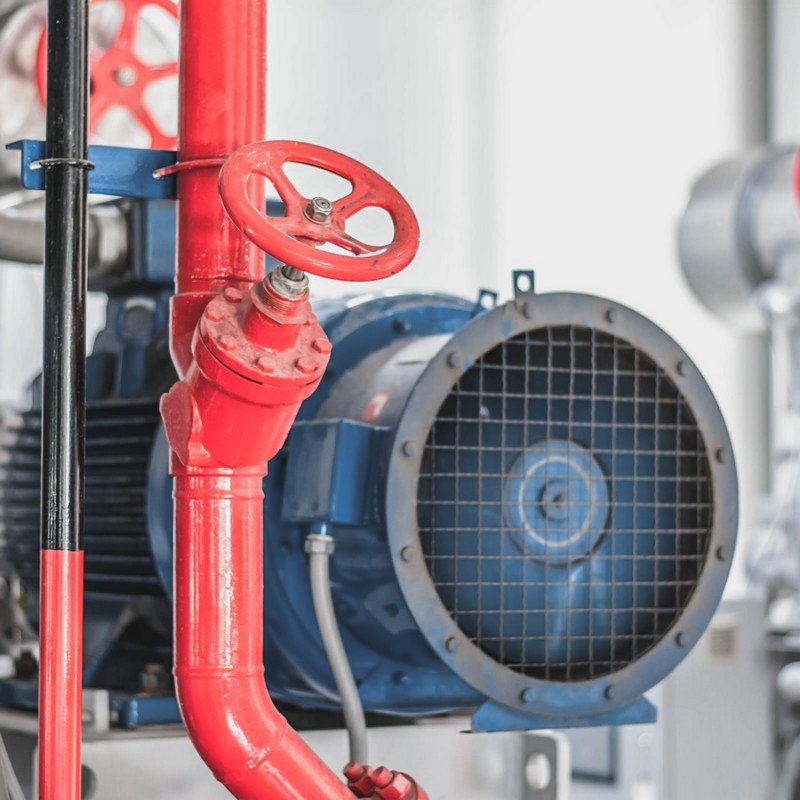

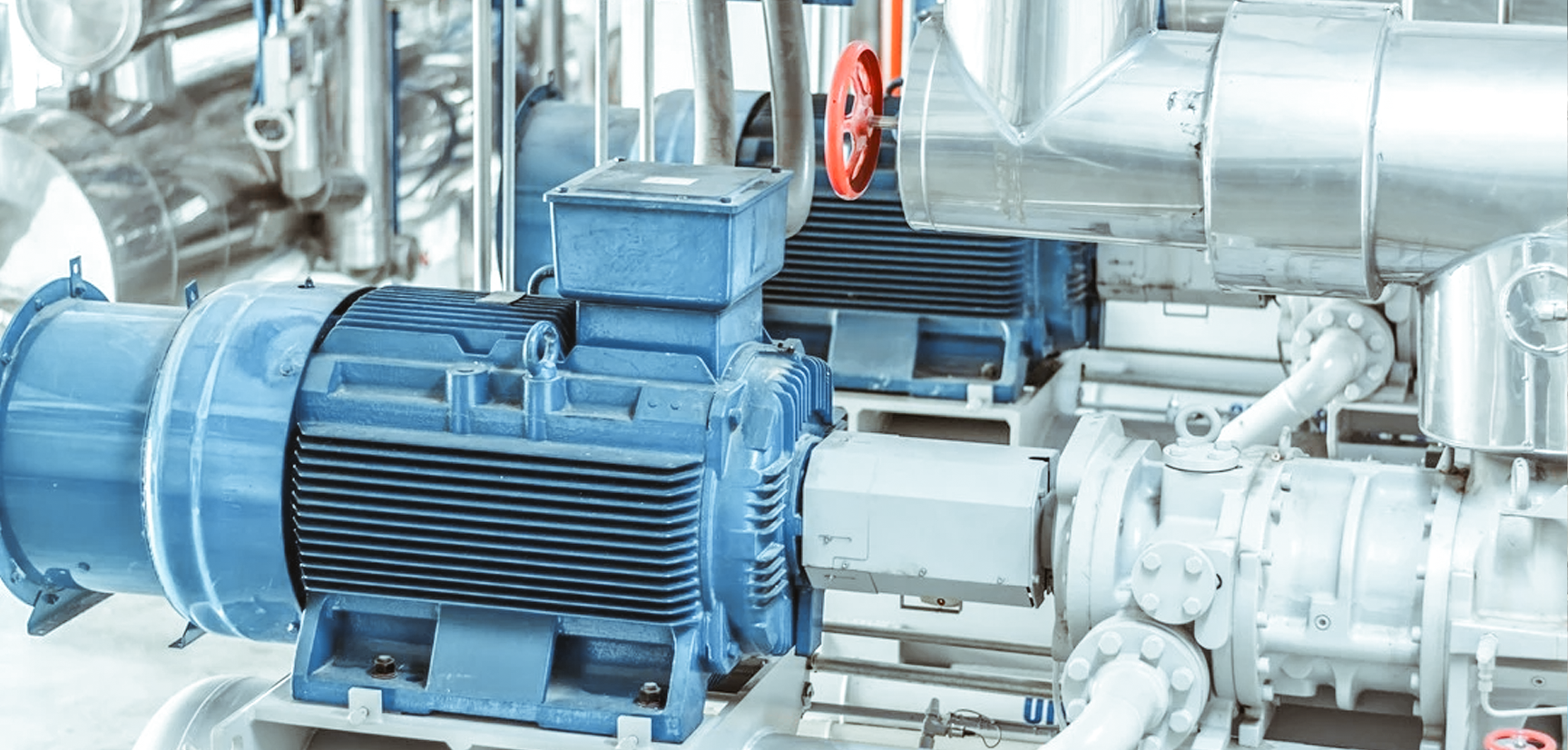

A compressor unit is a sophisticated device that consists of several essential components. It consists of a compressor fully equipped with control, regulation and safety instruments, shut-off fittings, an oil separator (in the case of reciprocating and rotary compressors), a clutch or belt transmission, a drive motor, auxiliary equipment and a condenser, a liquid refrigerant tank, a liquid refrigerant dryer (in the case of Freon units) and an optional regenerative heat exchanger. All these components are mounted on a common frame or supporting structure, and the duct connections intenTypes of condensing unitsded for external connections are properly prepared and blanked.

Types of condensing units

The design solutions of compressor units mainly depend on the cooling capacity and the method of condenser cooling. Based on the method of condenser cooling, condensing units can be divided into:

- Condensing units with water-cooled condenser

- Condensing units with air-cooled condenser

Condensers in chillers with a cooling capacity of up to 3.5 kW are usually air-cooled, where a forced cooling air flow generated by a fan is used. Condensers with gravity flow of cooling air are used in low-power refrigeration units.

Application of condensing units

Condensing units work with a variety of refrigeration equipment, such as refrigeration furniture (display cases, cabinets, store counters), cold rooms, ice makers, ice machines and air conditioners. It is crucial that the compressor unit be properly selected and installed to ensure its proper operation. These units must meet high technical requirements, such as high cooling capacity with low energy consumption and a high level of safety in use.

Accreditation

Quality accreditation - a guarantee of trust

The AB 308 Refrigeration Equipment Laboratory is accredited by the Polish Accreditation Center and specializes in testing refrigeration equipment.

Our team consists of qualified and experienced specialists who offer comprehensive assistance in the process of preparation for testing and the refrigeration equipment tests themselves. With our services, we provide customers with reliable and professional service at every stage of cooperation.

Contact information

Below you will find a list of contact information for COCH Refrigeration Equipment Laboratory

General Affairs

Laboratory manager

mgr inż. Dorota Niedojadło

+48 12 637 08 57

+48 667 600 635

laboratorium@coch.pl